7.3 Translation mechanism

The ..BHM\Heat_Movements\Tran directory includes three examples with load translation inside the oven:

- heat_3tran1.pro where one object moves iteratively between three positions in the xy-plane,

- heat_6tran1.pro where one object moves iteratively between six positions in the xy-plane,

- heat_4tran2.pro where two objects move iteratively in the xy-plane, each between its own four positions.

We shall focus on heat_4tran2.pro in further description.

In QW-BHM any number N of objects may be translated. Each of these objects must have a different name. The movement is along a straight line at any particular BHM heating time step, but the overall movement trajectory may be arbitrary. The user must ensure that the movement is physical - two different objects must not occupy the same volume of space at a time, and naturally, no objects may move outside the cavity.

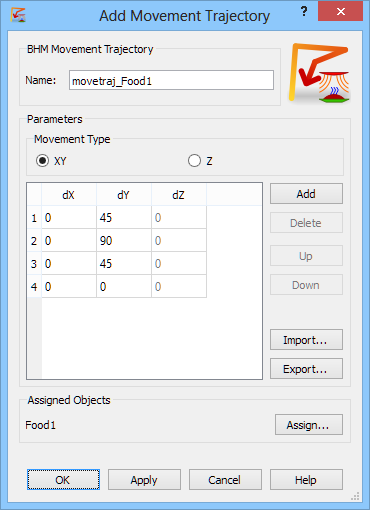

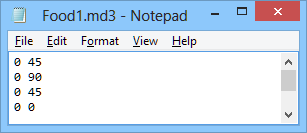

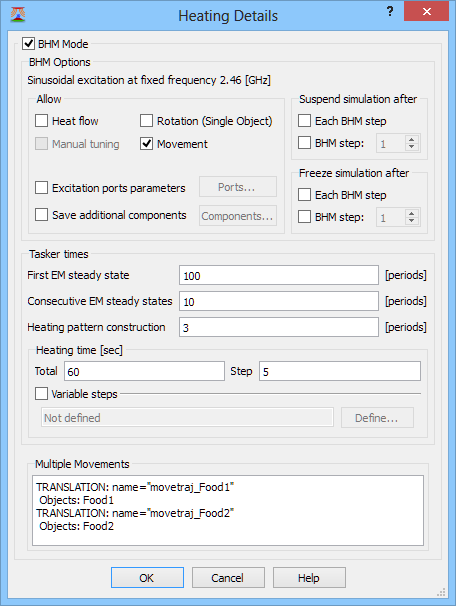

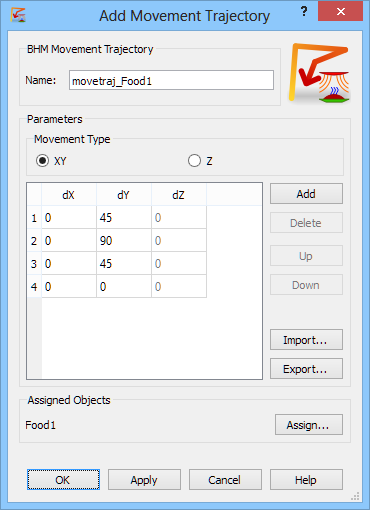

The objects to be translated during the heating need to have movement trajectory defined. The most convenient way to do this is via Add Movement Trajectory dialogue of QW-Editor (Fig. 7.3-2). The Add Movement Trajectory dialogue allows defining the consecutive positions of the moving object by declaring their shifts with respect to the object’s original position (note that the shifts reported in Simulator Log window are given with respect to the previous position). In the final stage the user needs to assign the defined movement trajectory to the object that is suppose to be moved during the heating.

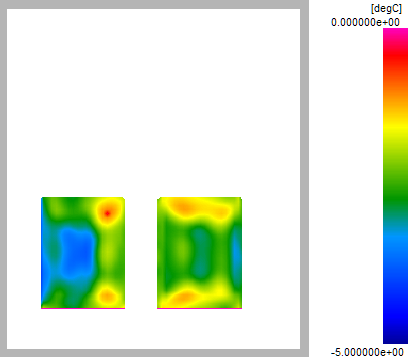

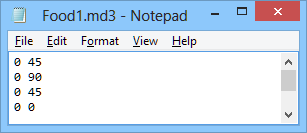

The movement can also be declared in the UDO script using MV_TRAN(oname) command. The command determines the object that needs to be translated via its name oname but (contrary to MV_ROTA) contains no additional movement parameters. The movement trajectory must be provided by the user in a text file oname.md3 in the project directory. Fig. 7.3-2 shows an example Food1.md3 file used for translating Food1 object in heat_4tran2.pro. The rule is as for delaration in QW-Editor, consecutive lines of the file contain x- and y-shifts of the object at consecutive BHM steps, with respect to the object’s original position. The *.md3 file can contain three columns lines describing x-, y- and z-shifts. The shifts are in the project units. Note that trajectories defined in Add Movement Trajectory dialogue can be exported to and imported from *.md3 file in the dialogue.

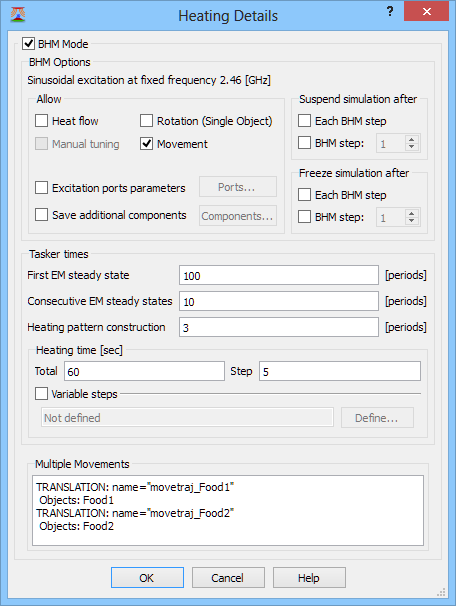

Note that consecutive BHM steps are determined in the Heating Details dialogue – they are multiples of the Heating time step. Once the last position of the movement trajectory is reached, its scanning re-starts from the first location, and the trajectory is looped this way.

BHM iter.

|

Min temp

|

Max temp

|

|

|

1

|

-4.99

|

-2.74

|

|

2

|

-4.57

|

-2.13

|

|

3

|

-4.31

|

-1.45

|

|

4

|

-3.94

|

-1.12

|

|

5

|

-3.63

|

-1.01

|

|

6

|

-3.46

|

17.80

|

|

7

|

-3.29

|

28.74

|

|

8

|

-3.04

|

31.86

|

|

9

|

-2.96

|

56.41

|

|

10

|

-2.90

|

68.50

|

|

11

|

-2.82

|

73.47

|

|

12

|

-2.76

|

80.00

|

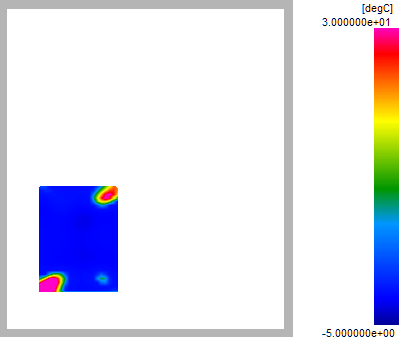

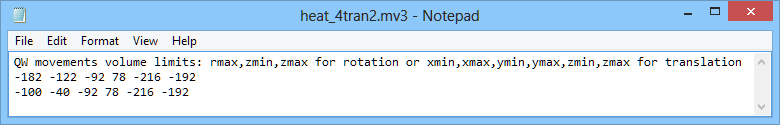

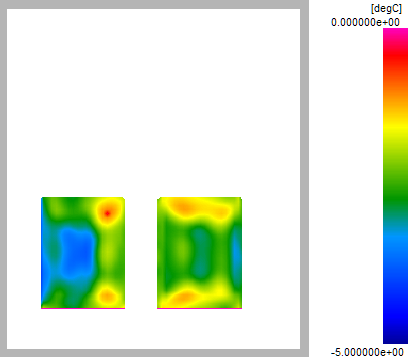

Fig. 7.3-1 Temperature in heat_3tran1 project, and final temperature pattern across the load (in -5÷30°C scale, in layer 8).

Fig. 7.3-2 The Add Movement Trajectory dialogue, listing of the Food1.md3 file describing consecutive x and y positions of the Food1 object, and the Heating Details dialogue of heat_4tran2.pro indicating the translation of two objects with BHM step of 5 sec.

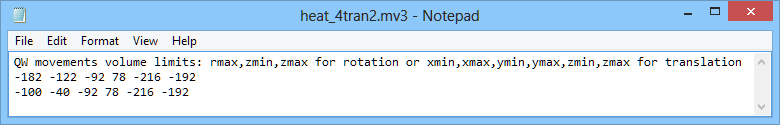

Fig. 7.3-3 Listing of the heat_4tran2.mv3 file describing the limits of cuboidal volumes wherein Food1 (second line) and Food2 (third line) are moved in the heat_4tran2.pro.

|

BHM iter.

|

Min temp

|

Max temp

|

|

|

1

|

-5.00

|

-3.52

|

|

2

|

-4.96

|

-2.81

|

|

3

|

-4.88

|

-2.54

|

|

4

|

-4.83

|

-2.13

|

|

5

|

-4.81

|

-1.78

|

|

6

|

-4.76

|

-1.53

|

|

7

|

-4.66

|

-1.45

|

|

8

|

-4.61

|

-1.35

|

|

9

|

-4.55

|

-1.22

|

|

10

|

-4.48

|

-1.03

|

|

11

|

-4.40

|

4.39

|

|

12

|

-4.35

|

10.63

|

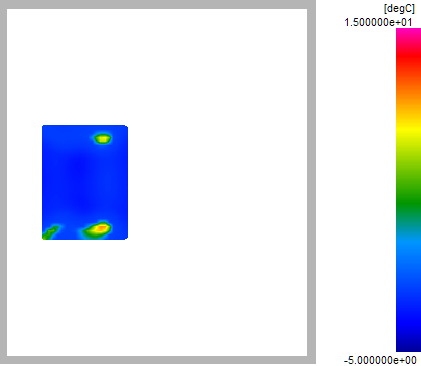

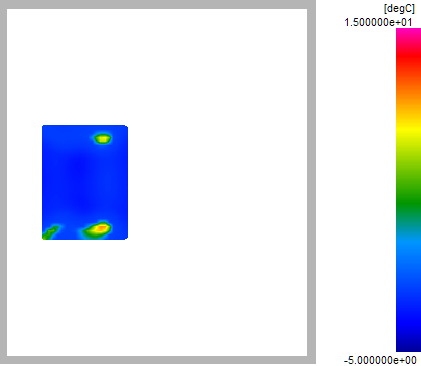

Fig. 7.3-4 Temperature in heat_4tran2 project, and final temperature pattern across the load (in -5÷0°C scale, in layer 8).

|

BHM iter.

|

Min temp

|

Max temp

|

|

|

1

|

-4.99

|

-3.59

|

|

2

|

-4.94

|

-2.04

|

|

3

|

-4.68

|

-1.37

|

|

4

|

-4.38

|

-1.23

|

|

5

|

-3.96

|

-1.10

|

|

6

|

-3.71

|

-1.10

|

|

7

|

-3.61

|

5.21

|

|

8

|

-3.55

|

13.74

|

|

9

|

-3.16

|

21.64

|

|

10

|

-2.91

|

26.47

|

|

11

|

-2.78

|

43.13

|

|

12

|

-2.73

|

49.78

|

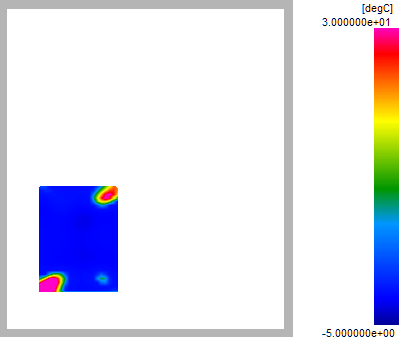

Fig. 7.3-5 Temperature in heat_6tran1 project, and final temperature pattern across the load (in -5÷15°C scale, in layer 8).