8.1 Heating Details

The Heating Details dialogue with options for Basic Heating Module process can be invoked:

· with the ![]() command in

command in ![]() button in Model tab

button in Model tab

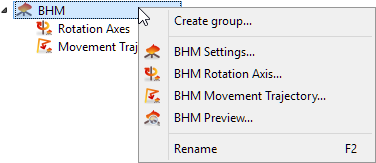

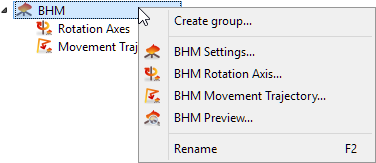

· with the ![]() command from BHM group context menu in the Tree View

command from BHM group context menu in the Tree View

· with the ![]() button in BHM tab

button in BHM tab

· with the BHM->BHM Settings… command from main menu

BHM Mode option checked, indicates that Basic Heating Module is active.

The Allow frame contains the following options:

· Heat flow – when checked causes that heat transfer analysis will be performed at each BHM step, if a proper Heat Flow module is set in Set Tools of QW-Simulator, and if all thermal media parameters are defined in media *.pmo files. Refer to Basic Heating Module: Heat Flow modelling regime chapter for more details.

· Manual tuning – when checked enables manual mode for frequency tuning scenarios. Refer to Basic Heating Module: Frequency tuning chapter for more details.

· Movement – when checked causes that the multiple loads will be rotated or moved at each BHM step according to BHM Rotation Axes or BHM Movement Trajectories defined. Refer to Basic Heating Module: Object movements chapter for more details.

· Excitation ports parameters – when checked causes that the excitation ports parameters will change after each BHM step according to settings in the BHM Excitation Port Parameters dialogue available after clicking Ports… button. This option is not available in this version of QW-Modeller.

· Save additional components – when checked causes that the additional components will be saved by QW-Simulator after each BHM step. Additional components can be set in the Components dialogue available after clicking Components… button. By default, the temperature patterns after consecutive BHM steps are saved in files.

Suspend simulation after options allow suspending the simulation after each or after clearly specified BHM step.

Freeze simulation after options allow freezing the simulation to the *.sfr file after each or after clearly specified BHM step.

Tasker times parameters are used to set physical time steps and FDTD iterations in tasker files automatically generated by QW-Editor, and are specified as numbers of periods of the excitation signal:

· First EM steady state - number of periods after which the electromagnetic steady state of simulation will be reached (based on either watching the fields and power, or on previous experience with a similar scenario). Only then the simulation of heating can start by performing the first thermal iteration. Setting First EM steady state to 0 periods activates manual mode of QW-BHM in QW-Simulator.

· Consecutive EM steady states - number of periods after which the electromagnetic steady state after the previous thermal iteration will be reached. Typically, this is less than the number of periods for First EM steady state by a factor of ten.

· Heating pattern construction number of periods for heating patter construction. Each of the thermal iterations requires the data on dissipated power envelope inside the sample to be collected. Note that it must be at least half a period, and preferably a few periods, due to finite time resolution.

Heating time parameters are used to set the heating times for BHM process:

· Total - number of seconds for the whole BHM heating process

· Step - number of seconds for heating in each BHM step. Number of BHM steps is calculated from Total and Step parameters.

The general rule is that number of BHM steps is the integer part of the Total/Step ratio. For the residue the following rules are applied:

1. if the residue is equal to or larger than the half of Step – additional BHM step is added with heating time set to the residue:

For Total=13 and Step=5 we obtain 3 BHM steps with the following heating times:

Step 1: heating time=5 seconds

Step 2: heating time=5 seconds

Step 3: heating time=3 seconds

2. if the residue is less than the half of Step – the rest will be added to the heating time of the last BHM step:

For Total=12 and Step=5 we obtain 2 BHM steps with the following heating times:

Step 1: heating time=5 seconds

Step 2: heating time=7 seconds

· Variable steps – when checked allows defining different heating time for each BHM step. It can be done in the BHM Heating Steps dialogue after clicking Define… button. The total heating time is the sum of all defined heating times and the number of BHM steps is the number of all defined heating times. When using it together with BHM Rotation Axis, the negative value of heating time can be used for changing the rotation direction for that particular BHM step.

Python code

The python code, which can be useful when creating project scripts, generated by Heating details dialogue for default parameters:

App.ActiveDocument.QW_BHM.AllowBHM = True

App.ActiveDocument.QW_BHM.AllowHFM = False

App.ActiveDocument.QW_BHM.ManualTuning = False

App.ActiveDocument.QW_BHM.AllowMovementAndRotation = False

App.ActiveDocument.QW_BHM.PortsSwitching = False

App.ActiveDocument.QW_BHM.ComponentsListUse = False

App.ActiveDocument.QW_BHM.ComponentsList = []

App.ActiveDocument.QW_BHM.FirstEmSteadyState = 100

App.ActiveDocument.QW_BHM.NextEmSteadyState = 10

App.ActiveDocument.QW_BHM.HeatingPatternConstruction = 3

App.ActiveDocument.QW_BHM.TotalHeatingTime = 60.00000

App.ActiveDocument.QW_BHM.HeatingTimeStep = 10.00000

App.ActiveDocument.QW_BHM.HeatingStepsListUse = False

App.ActiveDocument.QW_BHM.HeatingStepsList = []

App.ActiveDocument.QW_BHM.SuspendAfterEach = False

App.ActiveDocument.QW_BHM.SuspendAfterStep = False

App.ActiveDocument.QW_BHM.SuspendStep = 1

App.ActiveDocument.QW_BHM.FreezeAfterEach = False

App.ActiveDocument.QW_BHM.FreezeAfterStep = False

App.ActiveDocument.QW_BHM.FreezeStep = 1