2.4 Application of AMIGO

Automatic Meshing Intelligent Generation Option (AMIGO) provides more options of automatic mesh control, allows convenient settings of ports and post-processing frequency range from a single field, and defining one of simulation stop criteria. We hope that it will be enjoyed by both experienced and novice users.

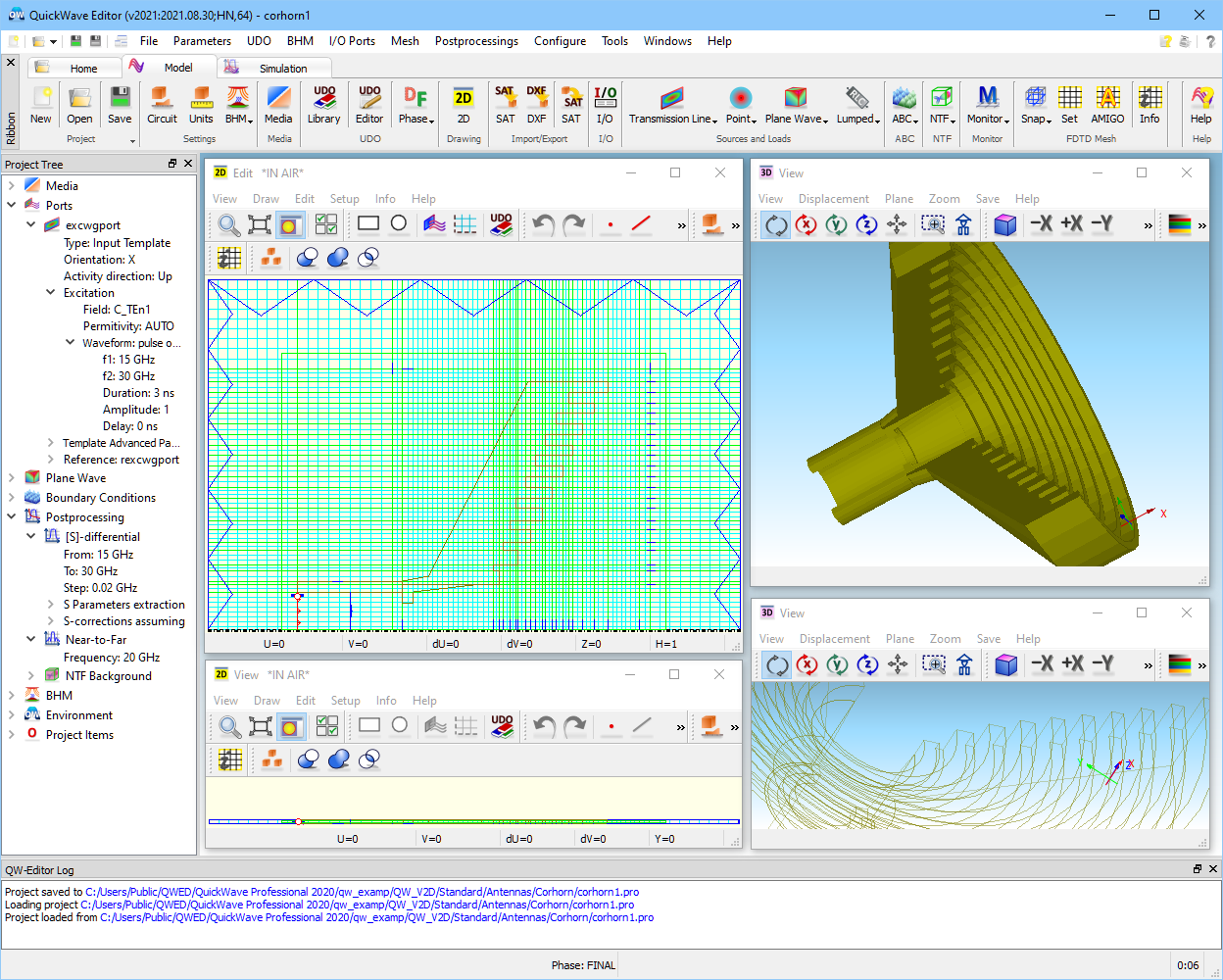

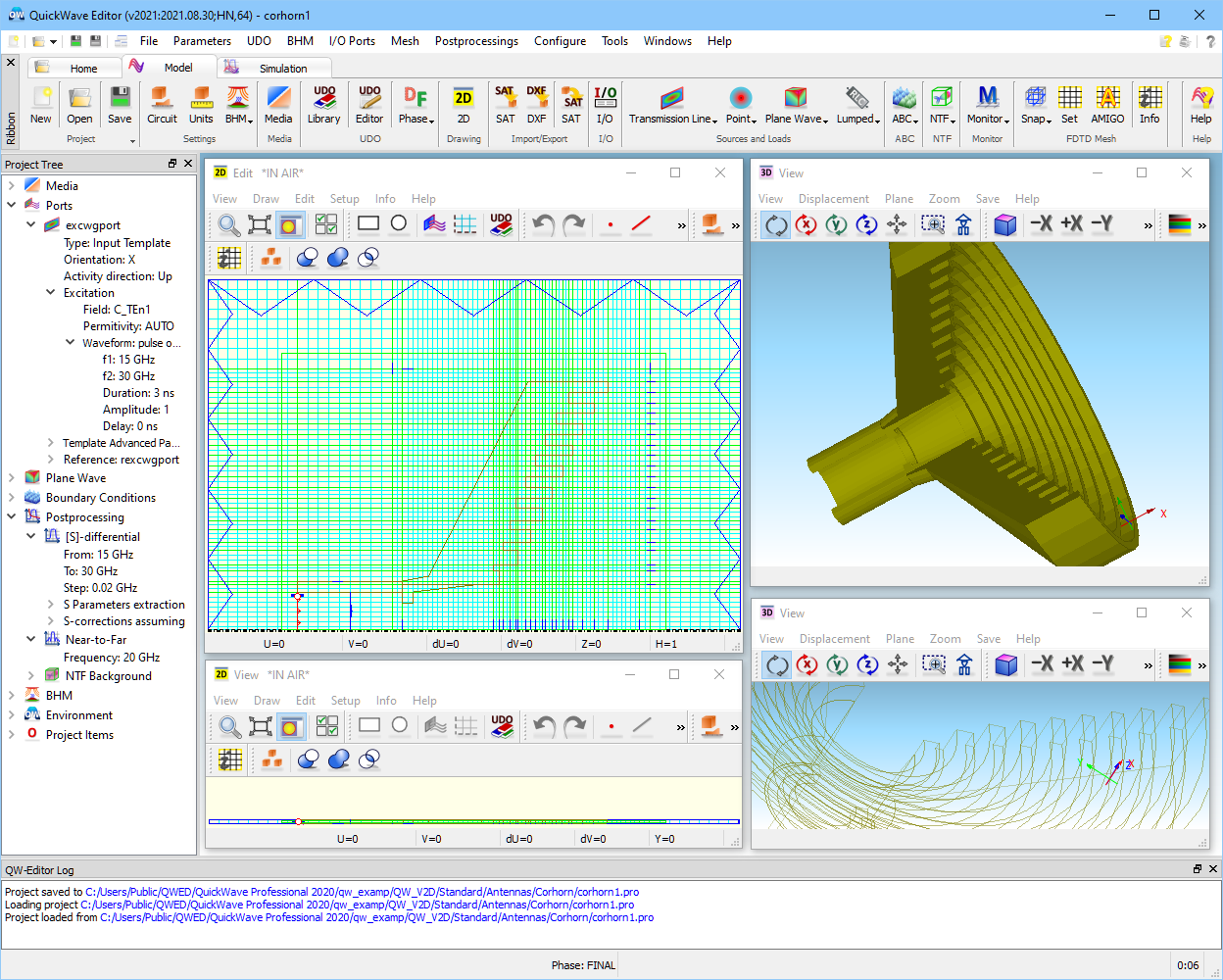

Fig. 2.4-1 Meshing in corhorn1 example.

Consider Standard/Antennas/Corhorn/corhorn1.pro example. It has been prepared using elib/V2Dhorns/anthorn.udo. It concerns an axisymmetrical corrugated horn. Default values of the parameters of anthorn.udo are taken. Fig. 2.4-1 shows the meshing displayed in QW-Editor 2D window. The meshing is enforced by commands incorporated in anthorn.udo. In particular, the UDO explicitly enforces mesh snapping planes along the edges of corrugations. The presence of those mesh snapping planes is marked by short blue segments displayed on the right and lower side of the picture. They are not absolutely necessary but they help in enhancing accuracy by enabling singularity corrections algorithms.

Now open another version of the same example: corhorn2.pro. It has been prepared using a simplified version of the UDO: anthornA.udo, in which all mesh snapping planes explicitly enforced at the edges of corrugations have been removed. The resulting meshing is presented in Fig. 2.4-2. We can see that the meshing is uniform. This may not be the best solution since the conformal meshing approximates FDTD cells with a rectangle cut by a straight line. This approximation may slightly alter the shape at the corrugation corners. Another point is special treatment of field singularities around sharp metal corners. QW-V2D software introduces special mathematical models (singularity correction models) to take such fields into account. However, these models are applied only when a metal edge is aligned with the FDTD cell limits. Thus the meshing of Fig. 2.4-2 would limit automatic application of those models and miss the opportunity of further accuracy improvement. When meshing is dense enough, the difference between calculations with and without field singularity models may be small. However, if we have just a few cells per corrugation depth, the absence of singularity models may corrupt calculated antenna parameters such as its maximum operating frequency.

Fig. 2.4-2 Meshing in corhorn2 example.

The considered corrugated structure can be easily meshed in an optimum way by AMIGO. This is exemplified by corhorn3.pro. Open this example in QW-Editor and press AMIGO ![]() button in Model tab to see the AMIGO dialogue as in Fig. 2.4-3. Detailed description of its commands and information can be found in AMIGO. Here we will comment only on the key parameters.

button in Model tab to see the AMIGO dialogue as in Fig. 2.4-3. Detailed description of its commands and information can be found in AMIGO. Here we will comment only on the key parameters.

The frequency range of interest has been declared between 15 and 30 GHz, with the required resolution df equal to 0.05 GHz. This means that we expect no resonances of the double-side band narrower than 0.05 GHz, and we want AMIGO to propose the number of FDTD iterations sufficient for obtaining 0.05 GHz resolution. Through the checkbox in the line below we have requested the band of interest to be automatically transferred to the Edit Transmission Line Port dialogue (to become the excitation band of the ports) as well as to the post-processings dialogues (to become the band of active post-processings). The frequency step in post-processings will not be 0.05 GHz but 20% of that value (0.01 GHz). The number of the frequency points in the FDTD post-processing has a minor effect on computer time and memory during simulations, and thus we can be rather generous here. With the frequency step equal to 20% of the requested frequency resolution we will have full information about the shape of the frequency-dependent characteristics even near the resonant frequencies.

In the central part of the dialogue of Fig. 2.4-3 we have chosen mesh control by AMIGO instead of manual. In this example, AMIGO meshing is instructed to produce minimum 12 cells per wavelength throughout the structure. It is preferable that geometrical details do not impose mesh snapping planes separated by a distance smaller than lmin=0.5 mm.

Fig. 2.4-3 AMIGO dialogue for corhorn3 example.

The resulting mesh by AMIGO is shown in Fig. 2.4-4. AMIGO has tried to place mesh snapping planes along the edges of all corrugations. However, a closer look reveals that some of the edges are not aligned with FDTD cells. In other words, some of the mesh snapping planes have been skipped. This is due to the requirement to “Avoid cells below lmin=0.5 mm” which has driven AMIGO to keep distance between mesh snapping planes above 0.5 mm. The resulting current smallest cell size in the structure is 0.45489. Keeping FDTD cell size above a certain limit serves to limit the computing time. Very small cells require appropriate reduction of the FDTD time step and thus increase the computing time of a particular simulation. Thus they should be avoided unless absolutely necessary.

In the lower FDTD iterations part of the dialogue, the software suggests 12700 iterations as sufficient for obtaining the desired frequency resolution df. This corresponds to 10 ns of the physical time, and is 24.4 bigger than the time needed by a wave in air to travel along the entire structure. Note that the number of FDTD iterations depends on the physical time needed to obtain the proper convergence of the physical processes, and also on the time step dt of the FDTD algorithm AMIGO. The value of dt chosen by the software is roughly proportional to the value of the current smallest cell size amin. Thus when amin decreases, the physical simulation time needed remains unchanged but the required number of the FDTD iterations increases. The last checkbox in the FDTD iterations block instructs QW-Simulator to suspend after the suggested number of iterations (12700).

Fig. 2.4-4 Meshing in corhorn3 example.

Press Start ![]() button in Simulation tab of QW-Editor to start simulations. After 12700 iterations the simulation is suspended indeed. We obtain well converged results of S11 as presented in Fig. 2.4-5.

button in Simulation tab of QW-Editor to start simulations. After 12700 iterations the simulation is suspended indeed. We obtain well converged results of S11 as presented in Fig. 2.4-5.

Fig. 2.4-5 Results of simulations of corhorn3 example.

In Automatic Meshing the priorities of mesh snapping planes are formally described. Let us introduce some hard mesh snapping planes. In QW-Editor open example corhorn3.pro. Press ![]() button in 2D window, double-click over element tb_fl and press the right mouse button. The Element Change dialogue of Fig. 2.4-6 appears. It shows that the tb_fl element (flange with corrugations) has got Amigo status of soft. This means that AMIGO will generate soft mesh snapping planes along the edges. Edges are understood by AMIGO as straight-line segments along the main axes X or Y, except for the edges aligned with the limits of the meshing area or ports. Soft further means that mesh snapping lines along the waveguide edges will have a soft (average) priority, and may be automatically removed by AMIGO if cells below lmin are generated by them.

button in 2D window, double-click over element tb_fl and press the right mouse button. The Element Change dialogue of Fig. 2.4-6 appears. It shows that the tb_fl element (flange with corrugations) has got Amigo status of soft. This means that AMIGO will generate soft mesh snapping planes along the edges. Edges are understood by AMIGO as straight-line segments along the main axes X or Y, except for the edges aligned with the limits of the meshing area or ports. Soft further means that mesh snapping lines along the waveguide edges will have a soft (average) priority, and may be automatically removed by AMIGO if cells below lmin are generated by them.

Change the tb_fl element status to hard edges, as in the right part of Fig. 2.4-6. AMIGO will now generate hard mesh snapping planes along the edges. Hard means that mesh snapping lines along the waveguide edges will have a hard (high) priority, and will not be automatically removed by AMIGO. Moreover, weak mesh snapping planes will be generated at a distance lmin on both sides of the hard plane. This is exemplified in Fig. 2.4-7. After opening AMIGO dialogue, we see that the smallest cell size has been reduced to 0.37421 mm and with the same physical time needed for well converged results the number of FDTD simulation has increased to 14300.

It can be verified that AMIGO meshing of corhorn3.pro is sufficient for very good accuracy, and introducing hard edges at the corrugations does not visibly change the results. We have presented this option for completeness. It may be useful in some special V2D cases of tiny metal details in an electrically large structure. We encourage the users to experiment with hard elements in such cases.

Fig. 2.4-6 Element Change dialogue with tb_fl element set soft as in the corhorn3 example (left) and changed to the status of hard edges (right).

Fig. 2.4-7 Meshing obtained with the horn of hard edges.