7.4 AMIGO

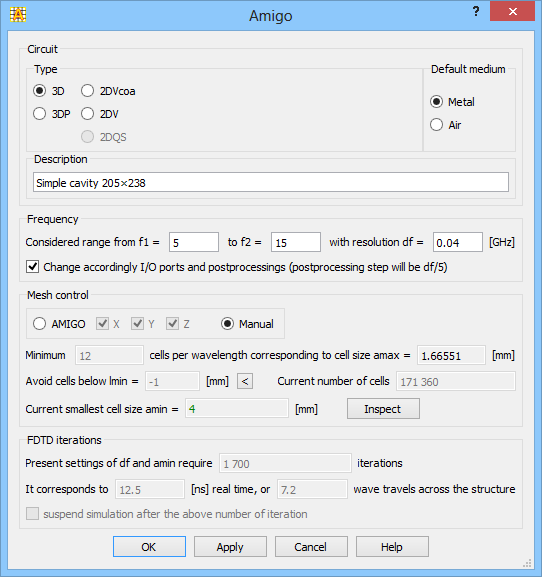

The ![]() button in Model tab and Parameters->FDTD Mesh AMIGO... and Mesh->FDTD Mesh AMIGO... commands from main menu invoke Amigo dialogue.

button in Model tab and Parameters->FDTD Mesh AMIGO... and Mesh->FDTD Mesh AMIGO... commands from main menu invoke Amigo dialogue.

Automatic Meshing Intelligent Generation Option (AMIGO) serves two purposes. Firstly, it optimises the meshing so as to provide requested wavelength resolution in all media, while avoiding unnecessarily small cells. Secondly, it allows fast setting of frequency ranges for all ports as well as S-Parameters, FD-Probing, and Power Available postprocessings. Additionally, it shows useful information about: details of structure definition that cannot be modelled within requested mesh constraints, and expected duration of the analysis. It also allows setting automatic stop criteria.

AMIGO dialogue contains four groups of commands:

· Circuit group of commands is a copy of chosen commands accessible also in Circuit dialogue.

· Frequency group allows setting the frequency band of interest. The limits of frequency band f1, f2 and resolution df are to be defined in the upper line of that group. If the checkbox below is checked, the frequency bounds f1, f2 will be copied to the I/O Ports Parameters dialogue as the frequencies f1 and f2 of the Excitation waveform , pulse of spectrum f1<f<f2. They will also be copied to all S-Parameters, FD-Probing and Power Available post-processings (and used for the active ones). The frequency resolution df will indicate the minimum number of FDTD iterations needed to obtain well converged results (see FDTD iterations group of commands for more explanations). The value of df /5 will be used as a frequency step for all active postprocessings.

· Mesh control group allows switching between automatic mesh generation by AMIGO or Manual. Note that the choice can be made for X, Y and Z directions, separately (Manual meshing will take place in the directions not checked for AMIGO meshing). AMIGO meshing is controlled by two basic parameters set by the user:

o Minimum number of cells per wavelength. AMIGO will prepare the meshing so that the wavelength-to-cell size ratio does not drop below this value in any material within the project. In typical applications, this number should be set to 10-15 but precise calculations may require refined meshing with 20 cells per wavelength or more.

o Avoid cells below lmin. It restricts automatic mesh refinements by AMIGO, guiding it to avoid generating too small FDTD cells. Very small cells may have a strong effect on computing time. Not only the total number of cells increases but also the FDTD step in time is automatically adjusted. The box with “<” sign allows setting a programme default value for lmin. In particular, it can be used when the software has no previous hints about lmin and displays value -1 in red. The default set by the “<” box is equal to half of the maximum cell size allowed in the medium of smallest wavelength (highest medium parameters values) within the project (i.e., equal to amax parameter displayed in the line above, divided by sqrt(εrμr) of that medium). The user may set a different value of lmin: lower to allow better mesh refinements or higher to further economise on the mesh. Attention: setting lmin higher than amax (the cell size in air, corresponding to the chosen minimum number of cells per wavelength, at the highest frequency in the chosen range) is inconsistent and may produce confused reaction of AMIGO.

The software also displays information about three other parameters, which depend on the above user’s choices. They are:

· amax - the cell size in air, corresponding to the chosen minimum number of cells per wavelength, at the highest frequency in the chosen range (f2), in air,

· the current number of FDTD cells in the project,

· amin - the smallest cell size in the currently existing FDTD mesh.

There are subtle relationships between amax, amin, and lmin that when obeyed assure correct AMIGO functioning. In general, the smallest cell size should not be smaller than half of the maximum cell allowed for the upper frequency in the medium of the shortest wavelength, and not smaller than lmin set by the user (this explains the default value of lmin described above). If amin obeys these conditions, it is displayed in green. Otherwise it is displayed in red suggesting that some details of the geometry or mesh snapping planes explicitly enforced by the user make the cell size smaller. The user is encouraged to press the button Inspect to investigate the cause of generating such a small cell. The obtained window shows the mesh snapping planes generated by the software. They are classified into four groups of priorities (Master, Hard, Soft andWeak). The meaning of those priorities is described later in this Section.

· FDTD iterations is a group providing information about the expected duration of the simulation. In particular it shows:

o The number of FDTD iterations needed to obtain the assumed frequency resolution df. From the Fourier transform properties, resolution df requires simulation time T=1 /(2 df). On the other hand, T=N*dt where N is the number of FDTD iterations and dt is the time step of the FDTD leap frog algorithm. The software automatically chooses dt so that it is proportional to the smallest cell size (amin) to obey the Courant stability criterion. Thus both amin and df influence the required number of iterations.

o Requested physical time of FDTD simulations T[ns] (see the previous paragraph). This parameter may be informative, especially in problems considering transients of pulses.

o The value of T expressed as the number of wave travels across the structure (assuming that the structure is filled with air). This value may be informative in the case of non-resonant structures of relatively big dimensions when we should set the simulation time long enough to allow the reflected wave to bounce back a few times, producing well converged simulation results.

We have one checkbox in the FDTD iterations group. It enforces suspension of the simulation process after N iterations (or in other words after time T).

In general, AMIGO tries to optimise the mesh taking into account the requested number of cells per wavelength in each medium as well as the geometrical properties of the structure. Although QW-3D uses a conformal FDTD method, accuracy may be enhanced when the geometrical details are well synchronized with the actual FDTD mesh. This can be obtained by introduction of Snapping Planes.

In most applications, the E-type of mesh-snapping planes are preferable because they provide the best conditions for accurate analysis of the most critical parts – edges of metal elements in the structure. Thus AMIGO tries to generate mesh-snapping planes of the E-type along edges of geometrical elements and passing through their vertices. However, in many practical projects such a process (if unrestrained) would result in generation of many small FDTD cells. This would cause a radical drop in the smallest cell size amin, and as a consequence - in the basic time step dt. This in turn would cause a drastic increase of computing time. To avoid such an effect, AMIGO sets priorities to the mesh-snapping planes and, in case of conflicts, eliminates those less important in order to try and keep the cell size above the declared value of lmin. There are four priorities of mesh snapping planes.

- weak – generated by AMIGO and eliminated in the first place when the condition for lmin cannot be met,

- soft – generated by AMIGO and eliminated in the second place when the conditions for lmin cannot be met,

- hard – generated by AMIGO upon the user’s declaration of a particular element as hard or of hard edges. They are not automatically eliminated by AMIGO when the condition for lmin cannot be met. Instead, they can be reviewed by the user using Inspect command in the Mesh Control group of AMIGO dialogue and possibly deleted upon the user’s specific request. Hard planes are mostly used for metal edges (like for example edges of a strip of a microstrip line). At metal edges, the fields are highly singular. When a metal edge is aligned with edges of FDTD cells, QW-3D automatically introduces special mathematical models of field singularities to enhance the modelling accuracy. Because of fast changing fields near such edges, it is also advisable to refine the FDTD cells near the edge. That is why the hard mesh snapping planes generated by AMIGO are accompanied by weak planes separated from the hard planes by the distance lmin.

- master – are mesh-snapping planes explicitly declared by the user outside the AMIGO system. They can also be viewed using AMIGO Inspect dialogue pressing Inspect button in the Mesh Control group.

From the AMIGO viewpoint, all the geometrical elements of the considered structure can be classified into four groups:

- disabled – no action by AMIGO,

- soft (default) – AMIGO generates soft planes along edges of these elements and at their limits, as well as weak planes passing through their vertices,

- hard edges – AMIGO generates hard planes along edges, soft planes along the limits and weak planes passing through the vertices,

- hard – AMIGO generates hard planes along edges and hard planes passing through the vertices.

The properties of each element can be changed manually in the Element Change dialogue.

The User Guide 3D: Application of AMIGO or User Guide V2D: Application of AMIGO chapters describe an examples with AMIGO meshing.