QuickWave Basic Heating Module (QW‑BHM)

Microwave heating co‑simulation for FDTD: temperature‑/enthalpy‑dependent media, multi‑body movement, and frequency tuning.

Faster iterations. Realistic physics. Production‑ready.

Why QW‑BHM

- Thermal iterations tied to EM steady states — restart from previous fields for faster convergence.

- Media that evolve with heating — ε, μ, σ and thermophysical data from

.pmotables vs temperature/enthalpy. - Movement & rotation — single or multiple bodies, independent speeds/axes, linear trajectories.

- Frequency tuning — automatic to the deepest resonance or manual; Rieke diagram for SWR insight.

- Heat transfer & fluid flow — internal Heat Flow Module (QW‑HFM) and internal Fluid Flow Module (QW‑FFM) coupling.

What QW‑BHM Does

Temperature‑Dependent Media

Constitutive parameters and thermo data read from .pmo tables; per‑cell updates via dissipated power patterns.

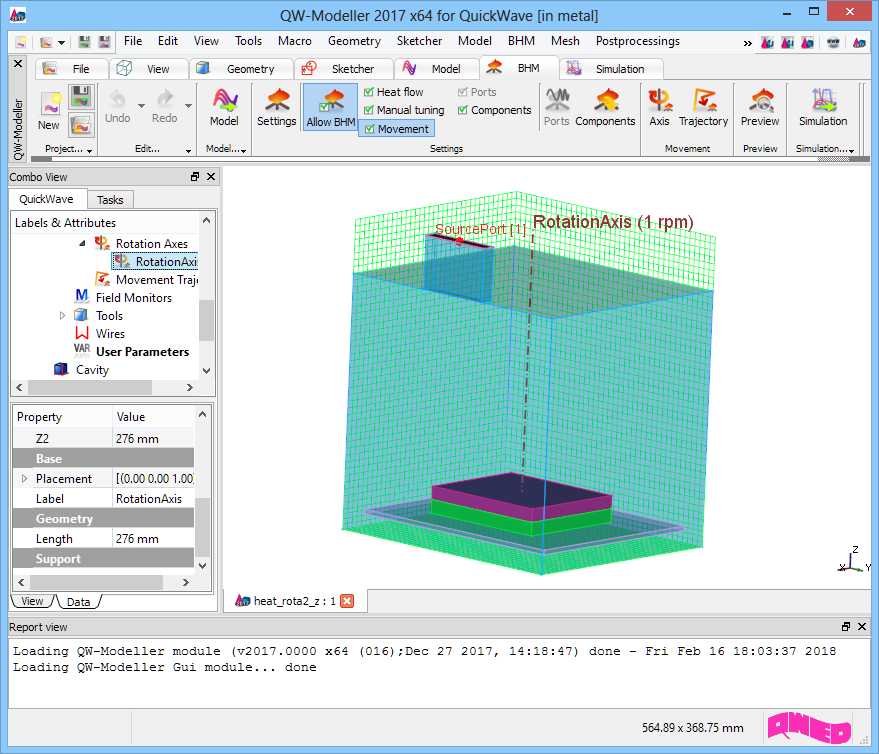

Movement & Rotation (Multi‑Body)

Turntables, stirrers, conveyors; independent axes and speeds; XY rotations, piece‑wise linear translations in XY/XZ/YZ planes.

Frequency Tuning

Auto tuning to the deepest in‑band resonance (solid‑state‑like) or user‑defined manual tuning; Rieke diagram for SWR.

Heat & Fluid Flow Coupling

Internal QW‑HFM and QW‑FFM exchange power, enthalpy, and temperature to capture diffusion and convection effects.

Batch or Manual Regimes

Exported taskers for fully automated steps or interactive control over steady‑state checks and heating time Δt.

Interfaces & Outputs

3D average power, enthalpy density, temperature fields; TestMesh inspection; reports each BHM step.

Applications

Domestic & Industrial Ovens

Optimize coupling, uniformity, and cycle time with movement, tuning, and evolving media models.

- Turntables & mode‑stirrers

- Solid‑state or magnetron‑like regimes

- Hot‑spot mitigation

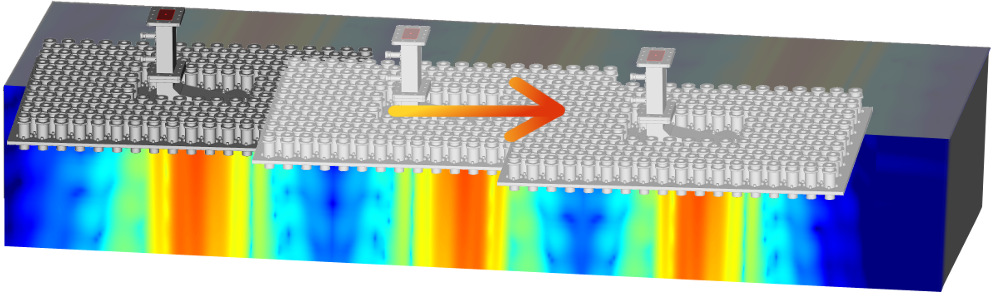

Tunnel Applicators

Conveyor translation, frequency sweeps, and heat diffusion for continuous processing.

- Piece‑wise linear motion

- Power deposition uniformity

- Throughput vs quality trade‑offs

Thawing & Tempering

Phase‑dependent properties via .pmo tables; conservative Δt selection for stable convergence.

- Rising σ and ε with temperature

- Avoid “jumping” across extrema

- Check TestMesh after each step

Timber, Rubber, Composites

Strong property variation with moisture/temperature; diffusion and convection effects with HFM/FFM.

- Nonlinear conduction

- Convective boundaries

- Multi‑material assemblies

De‑icing & Susceptor Processes

Localized heating with moving sources or loads; monitor power budgets and temperature ramps.

- Coupling efficiency tracking

- Ramped or stepped Δt

- Batch reporting

Custom Multiphysics Pipelines

Use QW‑OptimiserPlus to balance EM matching vs thermal targets; script batch studies.

- Multi‑objective goals

- Design of Experiments

- Parametric templates

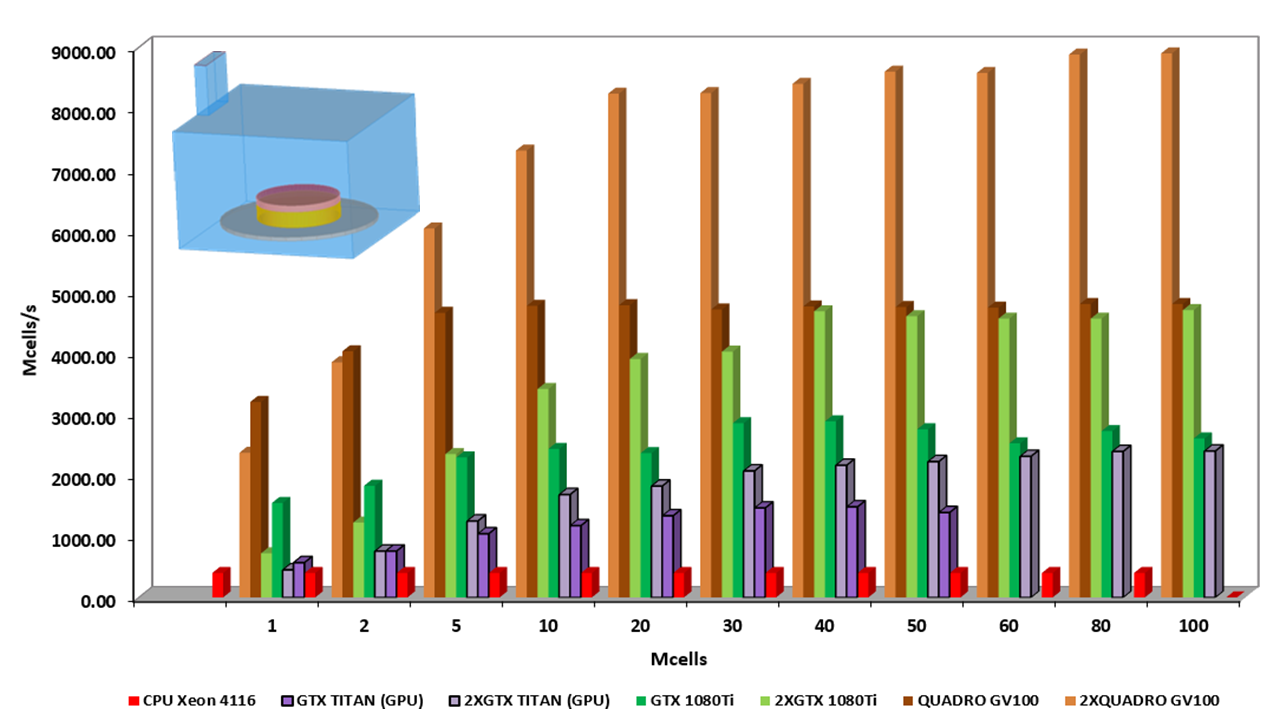

Modules & Ecosystem

- QW‑BHM — evolving media, multi‑body movement, frequency tuning, heat conduction coupling.

- QW‑OptimiserPlus — sweeps, batch mode, goals from fields/power/temperature.

- QW‑Modeller — parametric CAD for EM + heating workflows.

Heating Loop — In a Nutshell

- Run sinusoidal FDTD until EM steady state is reached.

- Compute average dissipated power P(x,y,z).

- Update enthalpy density H per cell using chosen heating time Δt.

- Update temperature from

.pmotables or ρ·C (fallback). - Perform movement/rotation (if enabled) — carry T and H with the load.

- Run internal QW‑HFM (and QW‑FFM if enabled) for diffusion/convection.

- Rebuild material matrices for new T/H and resume FDTD from prior steady fields.

- Repeat until thermal target/stop criteria are met.

Tip: choose Δt conservatively to avoid skipping extrema in media characteristics; increase “Consecutive EM steady states” or reduce movement step if transients persist.

Setup & Data Files

- .pmo per medium — tabulated ε, μ, σ, (optionally) Cp, density, and heat transfer vs T/H.

- Initial fields — define T₀ in QW‑Editor; enthalpy read from

.pmoif available else set to 0. - Export options — enable Allow BHM and open Details… to pick mode and tasker times.

- Convective BCs — define coefficients in

.pm2files for thermodynamic analysis. - Movement constraints — dielectric isotropic/anisotropic supported; dispersive media rotation not supported.

FAQ

Does QW‑BHM account for heat diffusion by itself?

Diffusion is handled via the internal QW‑HFM (Heat Flow Module) coupled with BHM. You can also enable the internal Fluid Flow Module (QW‑FFM) for convection.

How should I choose the heating time Δt?

Pick Δt so that media updates do not jump over extrema in ε/σ vs T/H. If changes are too small, add another Δt before resuming EM; if too large, apply a smaller corrective Δt.

Can I rotate any material type?

Rotation/translation are supported for dielectric isotropic/anisotropic media. Rotation of dispersive media is not supported. Metallic motion is allowed but be cautious about singularities if edges aren’t snapped to mesh.

Do I need .pmo files?

Strongly recommended. Without them, BHM falls back to constant ρ and Cp for temperature updates; you lose temperature‑dependent ε/σ accuracy.

Contact Sales

Tell us briefly about your heating scenario — load, movement, target temperature, and power. We’ll get back to you shortly.

Contact us using the form

Do you have any questions?

Contact us, we will provide answers.